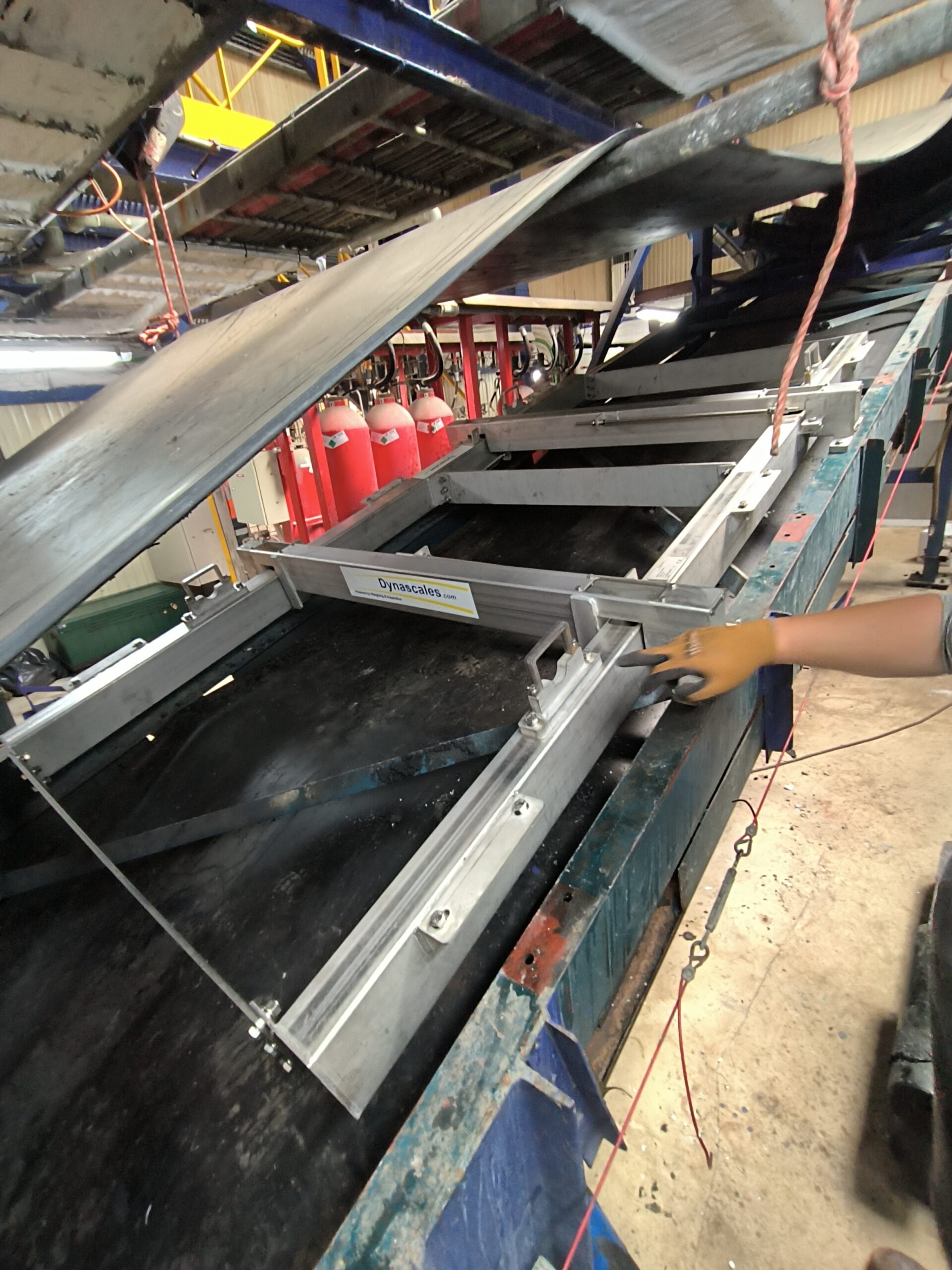

We recently tackled a unique challenge with one of our long-standing customers, a loyal partner of Thermo Ramsey, who required a conveyor belt weigher installed in a space that was far from ideal. Despite the limited space, we engineered a tailored solution utilizing three weighing troughs, ensuring precise and reliable performance. We made a custom made 10143 Conveyor belt weigher frame in SS304.

In addition to the space constraints, the client requested the integration of semi-automatic reference weights on the belt weighers. We successfully mounted these together, resulting in a seamless operation. This setup now allows the client to accurately weigh sugar beets, ensuring precise sugar production for the upcoming campaign.The entire 1014 frame, made from Inox 304, operates at a capacity of 750 kg/h with a belt width of 1600mm. Due to the complexity of the frame design, it was assembled on-site as a DIY-kit (do-it-yoursef) , ensuring a perfect fit in the challenging space.

The project was a resounding success, further strengthening our client’s trust in Dynascales’ ability to deliver custom, high-quality solutions.