Our universal WI301 Integrator

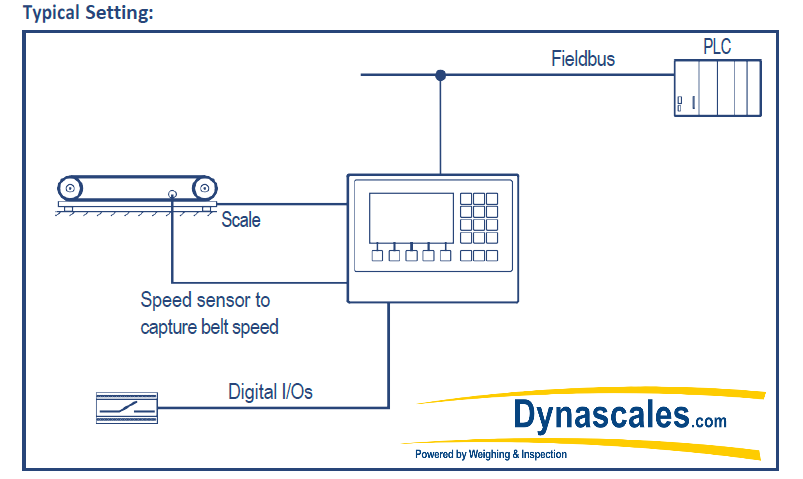

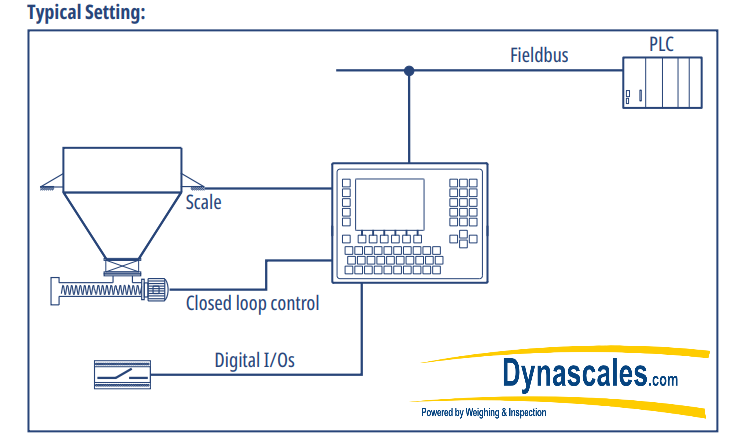

The Dynascales electronics are essential tools for accurately measuring the flow of material on conveyor belts in various industries. However, to ensure that belt scales function properly and provide accurate readings, several accessories are required.

One of the essential accessories for belt scales is an integrator. Integrators process the signal from load cells and calculate the total weight of the material being transported on the conveyor belt. Integrators come in different I/Os and communication protocols, depending on the specific application and the desired level of automation.

Our universal WI301 Integrator

The WI301 weighing integrator is a cutting-edge product that offers many advantages for industrial weighing applications. With its color screen, user-friendly interface, and compatibility with various communication protocols, the WI301 is an excellent choice for businesses looking for an accurate, reliable, and user-friendly weighing integrator. The WI301 has an OIML certificate according to the EEC directive, class 2, 1 and 0.5.

One of the most significant advantages of the WI301 is its color screen and standard IP69K protection in stainless steel. This feature makes it easy to read and interpret the data, ensuring that users can quickly and accurately assess the weight measurements of their products. Additionally, the user-friendly interface allows operators to easily navigate the settings and calibrate the weighing system.

The WI301 is also designed to be compatible with various communication protocols, including Profibus, Profinet, Ethernet TCP/ IP, Ethernet IP and 4-20mA, making it easy to integrate with existing systems. This flexibility means that businesses can choose the most appropriate communication protocol for their specific application, enabling seamless integration with other devices on the production line.

Another advantage of the WI301 is its versatility in installation. It is available in both field and panel mount versions, making it suitable for various industrial settings. Additionally, its IP69K rating ensures that it is resistant to water and dust, making it an excellent choice for harsh and demanding environments. The stainless steel construction also makes it durable and corrosion-resistant, ensuring long-lasting performance even in challenging conditions