Our WI800 Digitizer

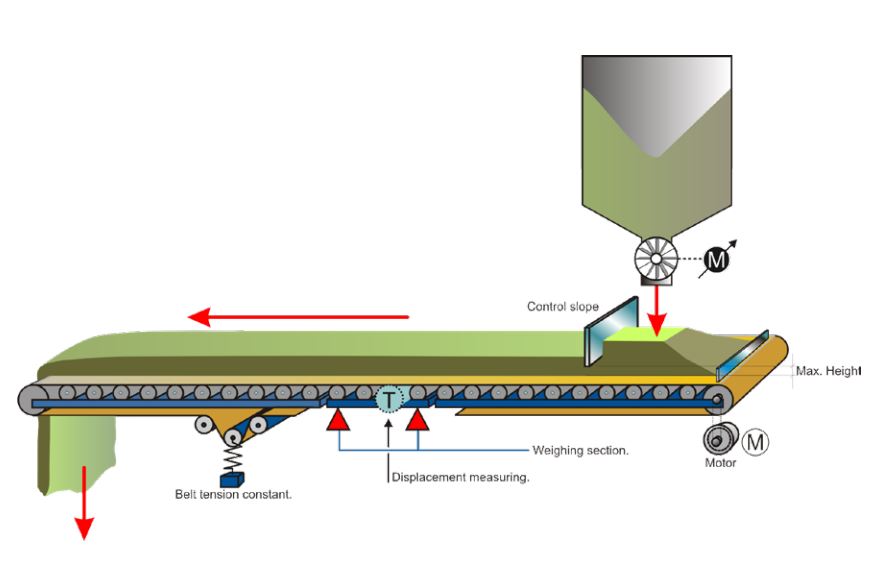

The Dynascales electronics are essential tools for accurately measuring the flow of material on conveyor belts in various industries. However, to ensure that belt scales function properly and provide accurate readings, several accessories are required.

The WI800 series is a certified serie that offers solutions for problem free connections of strain-gauge

load cell based measuring with any supervisory and/or control system. The series exists of 6 digitizers with

different communication options. There is also a series of fixed software is available, making it possible to

use the WI800 certified series as a mini controller.They all are easy DIN-rail mountable, and can be used as a stand-alone digitizer or as a buslink system. Up

to 32 digitizers can be coupled in one buslink system. Configuration of the device can even be done from behind your desk using the free software.

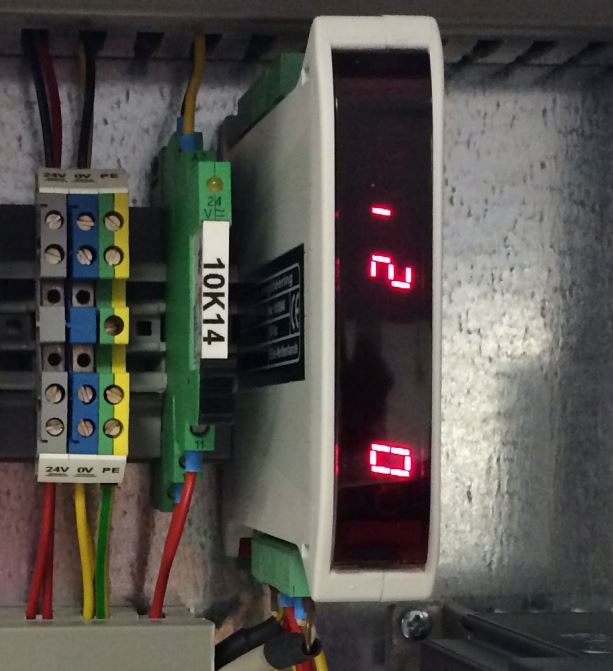

Trouble shooting is made easy by the small on board display, giving you a fast overview of the WI800 status.

WI800 Digitizer/ Amplifier

Our WI800 digitizer

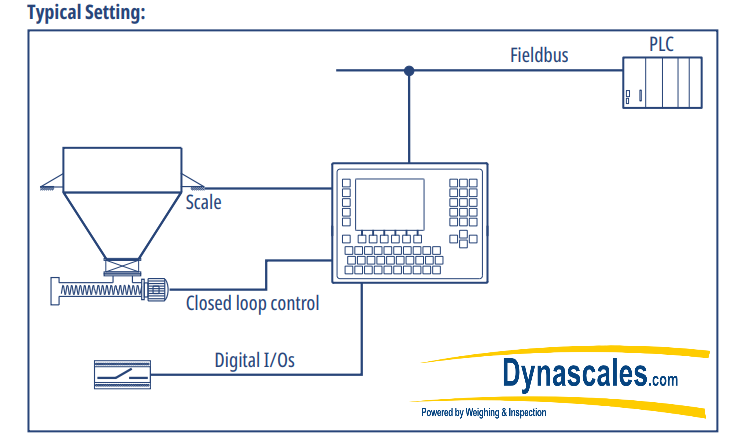

The industrial weighing terminal WI8100 BELT captures continuously the quantity of bulk material conveyed over a belt weigher for both, batching and receiving operations. WI800 BELT connects to a belt weigher structure with one load receptor with one or several analog loadcells.

The low budget weighing terminal is suitable for DIN- rail mounting.

The Dynascale approach of precise and fast measurement help to avoid waste of recourses and therefore help to save money. The quickly obtained clean and stable weighing signal from our fast revolutionary digital filters reduce the signal stable waiting time, improving the machine speed and therefore product capability

and profitability. Dynascale amplifiers and controllers ensure precise measurement, quick digitalization and fast responds time, bringing you one step closer to flawless production line which saves time and money.

All our amplifiers/digitizers and controllers are designed, manufactured in our Netherlands facility to maintain best of class quality control, reliability and performance.

Powerfull Controller

To control and regulate the continuous flow of bulk material, belt weighing systems are used. The Dynascale WI800 belt weighing approach detects every change in the mass flow enabling precise measurement, control and flow regulation. Our solutions help in reducing product spillage and increasing the factory’s efficiency by communication the most accurate flow. Developed for the WI800 is a belt weighing software to control. Flow measurement and totalising, based on strain-gauge load cells, where required in combination with a speed meter.

Features