Loading and unloading facilities

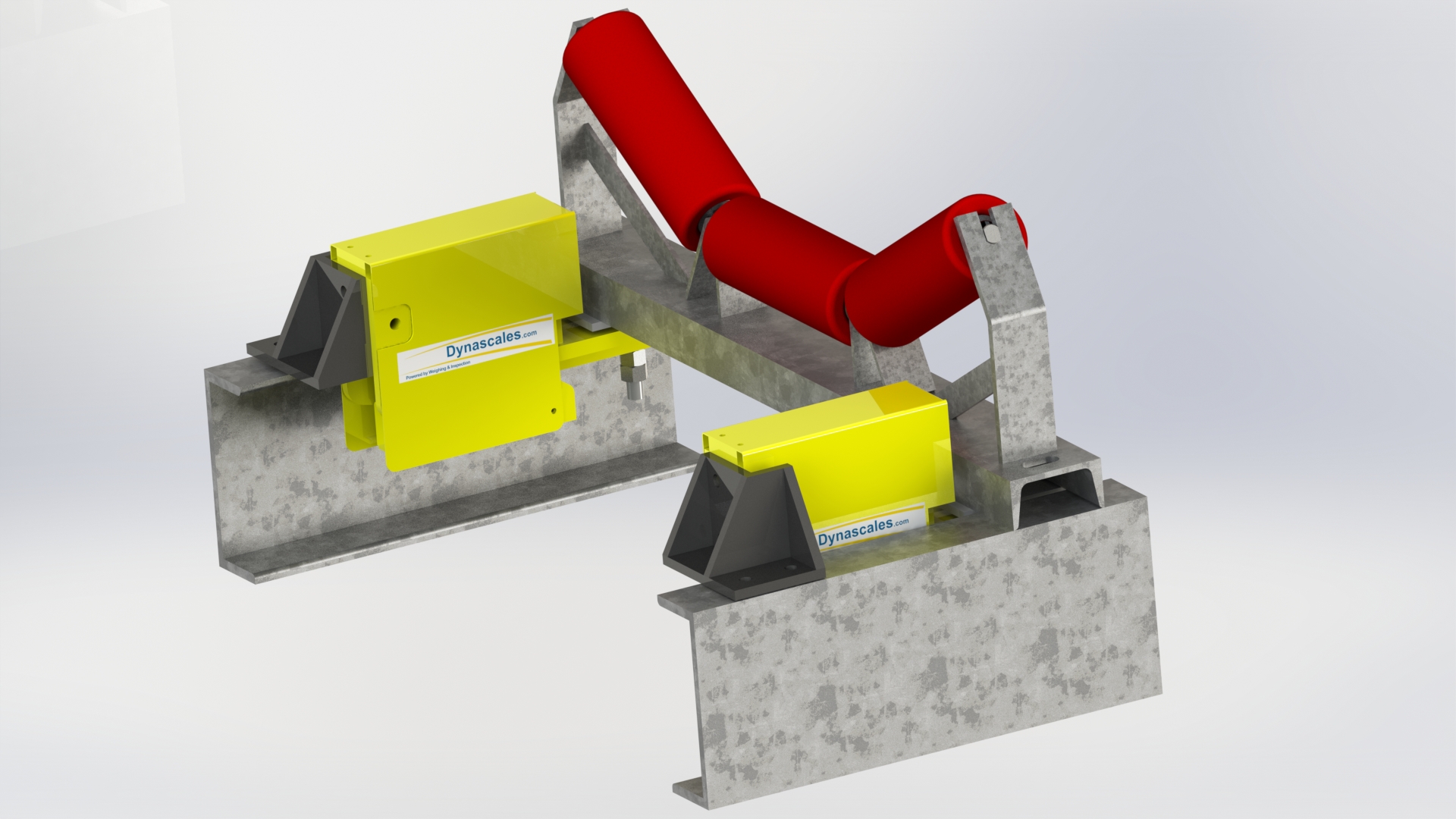

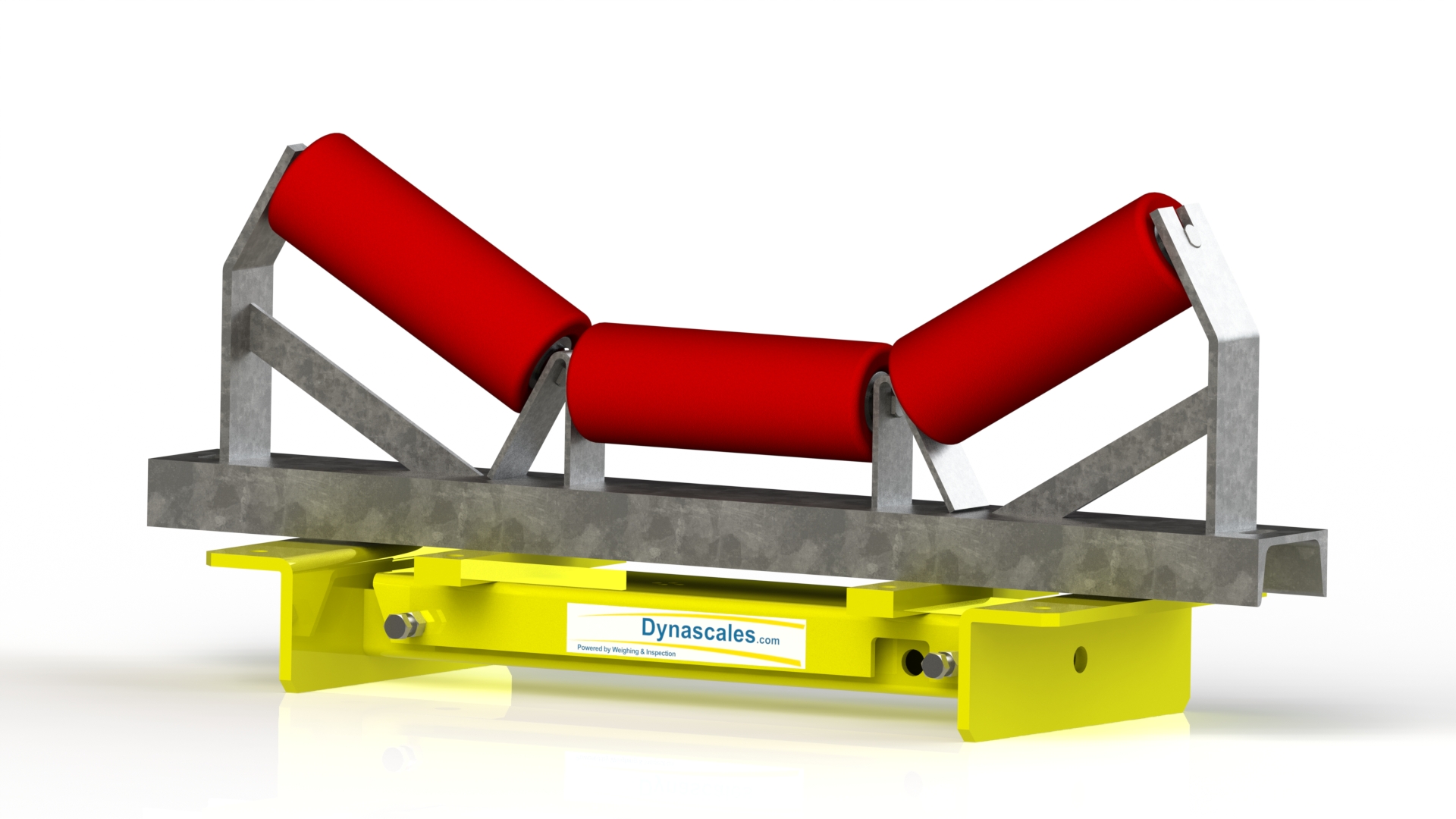

This application note highlights the benefits of utilizing the Dynascale belt weigher and Dynaflow solid flow measurement solutions in loading and unloading facilities.These Dynascale belt weigher provide accurate and reliable weighing and flow measurement capabilities, allowing for efficient management and control of material handling processes. It consists of a weighing frame, load cells, speed sensors, and a controller unit. Installed on the conveyor belt or material transfer system, the belt weigher continuously monitors the weight of the material in real-time, providing accurate data for process control and inventory management

Why Dynascales in loading and unloading facilities ?

Benefits for Weighing systems in loading and unloading facilities.

1.1 Accurate Weight Measurement:

The belt weigher ensures precise measurement of the material weight during loading and unloading. This accuracy is essential for billing purposes, inventory management, and compliance with industry regulations.

1.2 Real-time Monitoring and Control:

Operators can monitor the flow rate, totalized weight, and other relevant parameters in real-time. This enables immediate adjustments to loading/unloading rates, ensuring optimal throughput and preventing overloading or underloading of trucks, containers, or storage facilities.

1.3 Process Optimization:

By providing real-time data, the belt weigher enables operators to optimize loading and unloading processes. They can identify bottlenecks, adjust material flow rates, and optimize resource allocation to maximize efficiency and minimize downtime.

1.4 Inventory Management:

Accurate weighing data from the belt weigher facilitates precise inventory management. Operators can track the material flow, monitor stock levels, and plan for timely replenishment or distribution, avoiding inventory shortages or excesses.

1.5 Integration and Connectivity:

The Dynascale belt weigher seamlessly integrates with existing control systems and plant automation. It supports various communication protocols, allowing easy data exchange with other equipment and management systems for comprehensive process control and data analysis.

1.6 Reliability and Durability

The belt weigher is designed to withstand the demanding conditions of loading and unloading facilities. It is built to be resistant to dust, moisture, vibrations, and temperature variations, ensuring reliable operation and minimal maintenance requirements.