Paper mills

Using a Dynascale belt weigher in paper mills is important for several reasons. One of the primary reasons is to ensure accurate control of raw materials during the paper manufacturing process. The quality and consistency of the paper produced can be affected by variations in the weight of the raw materials used. Dynascale Belt weighers provide real-time weight data, which allows operators to precisely control the amount of raw materials being fed into the paper manufacturing process. This can help to ensure that the final product meets the desired specifications and quality standards.

Why Dynascales in paper mils?

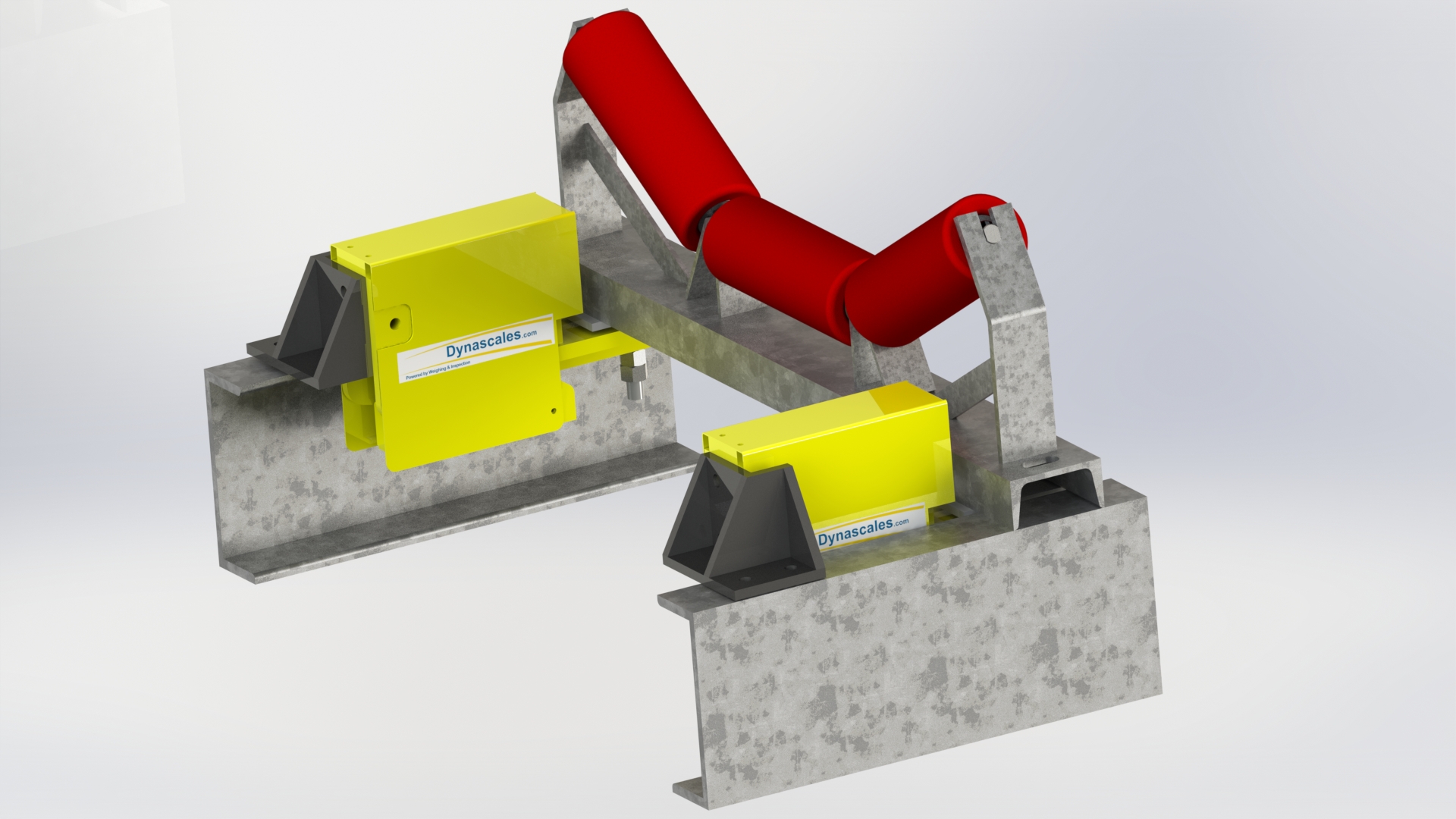

Our dynamic weighing scales are suitable for a wide range of applications in the industry. We offer a variety of models that can handle different weights and capacities.

Another reason for using Dynascale belt weighers in paper mills is to improve production efficiency and reduce material waste. Belt weighers provide accurate weight data, which allows operators to optimize the flow of raw materials and minimize material waste. By measuring the flow of raw materials, operators can identify and correct any issues that may be causing over- or under-use of the materials. This can help to reduce production costs, increase plant efficiency, and improve overall profitability.

Belt weighers can also help to ensure workplace safety in paper mills. Overloading conveyor belts with raw materials can cause them to malfunction or break down, posing a significant safety risk to workers. Dynascales Belt weighers can help to prevent overloading by providing real-time weight data, allowing operators to adjust the flow of materials as needed.

Our team of experts works closely with our clients to understand their specific needs and requirements. We strive to provide customized solutions that meet their unique demands, ensuring that our clients get the most out of our products.