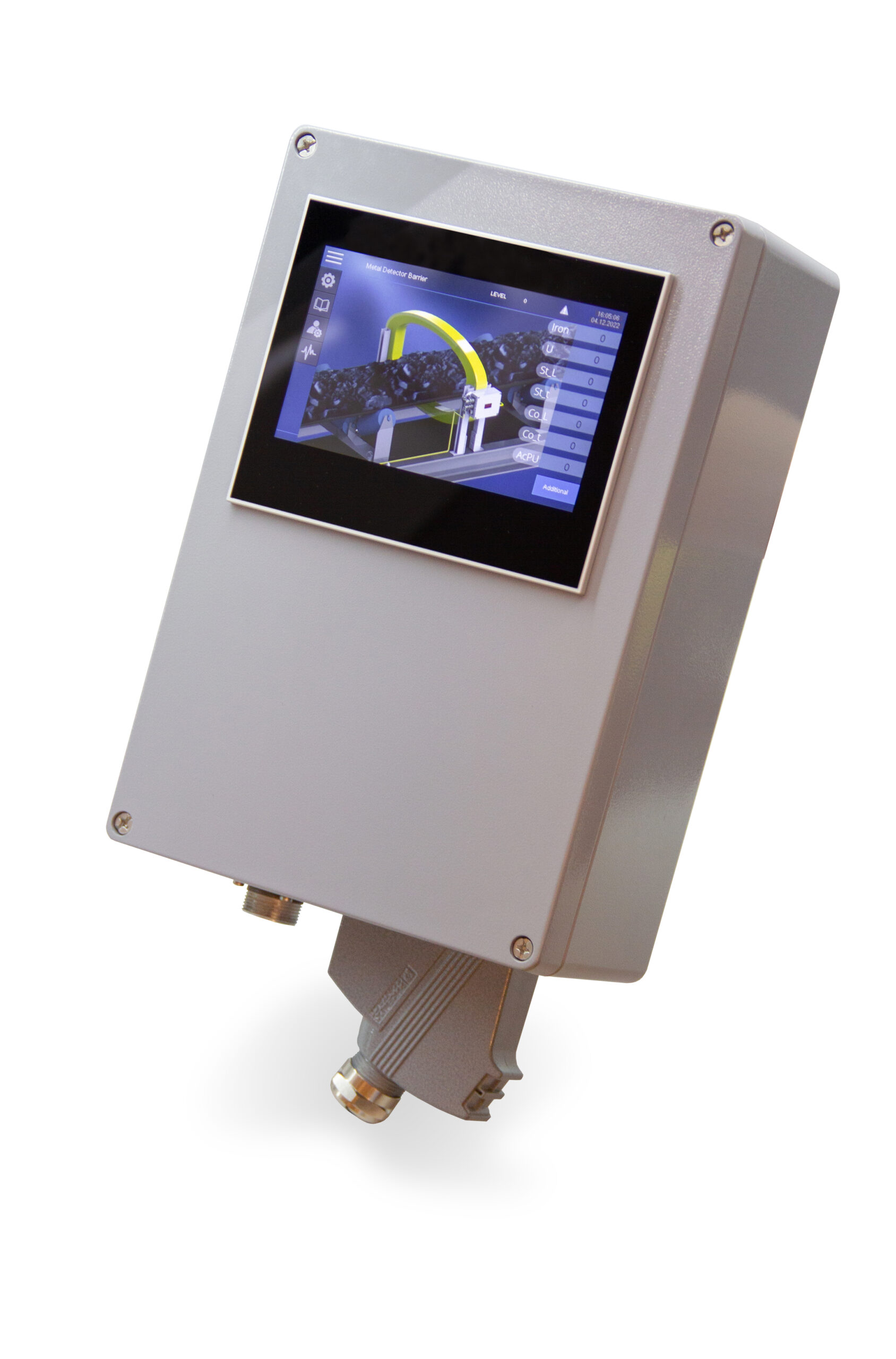

Tramp Metal Detector Barrier

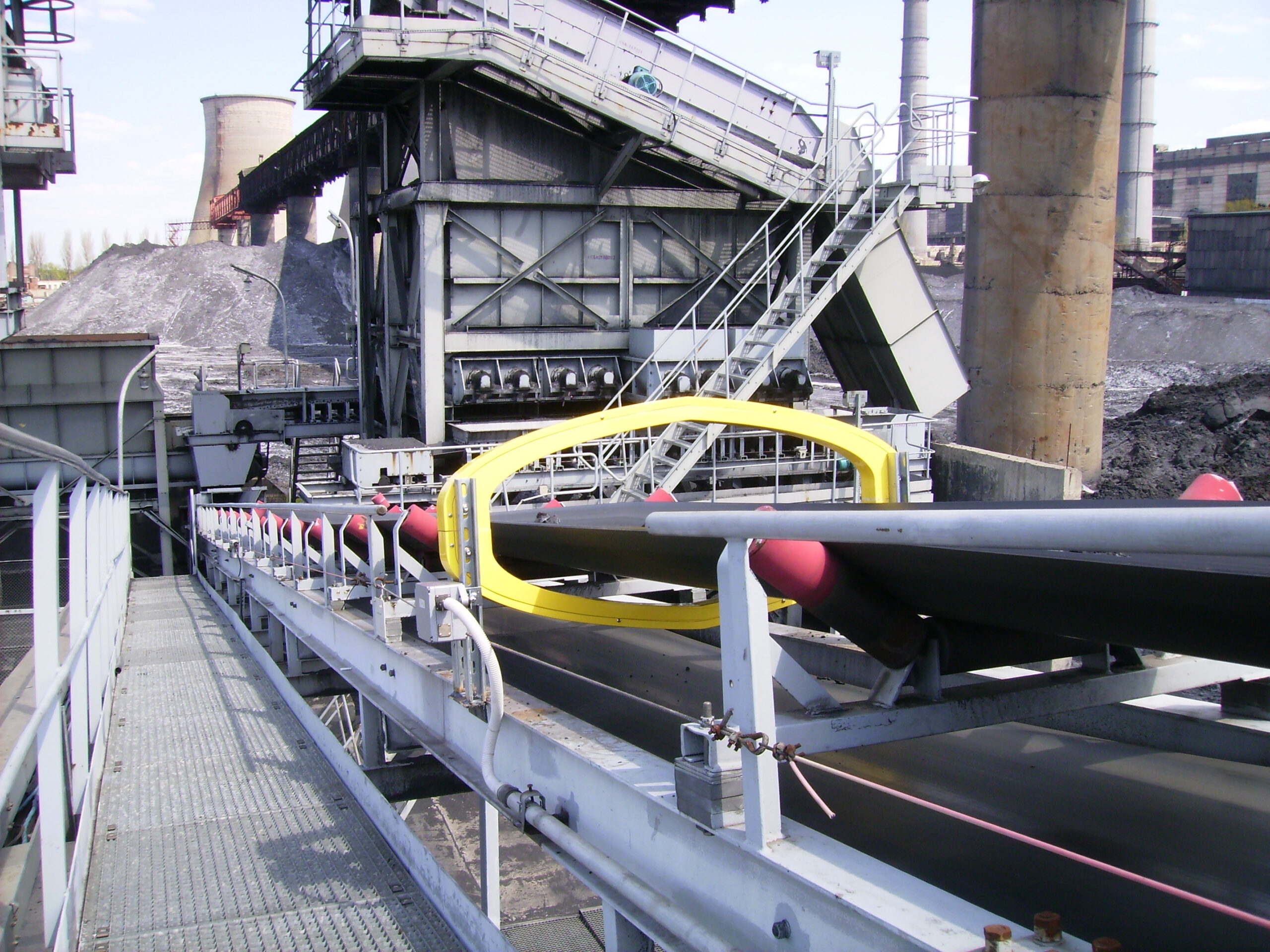

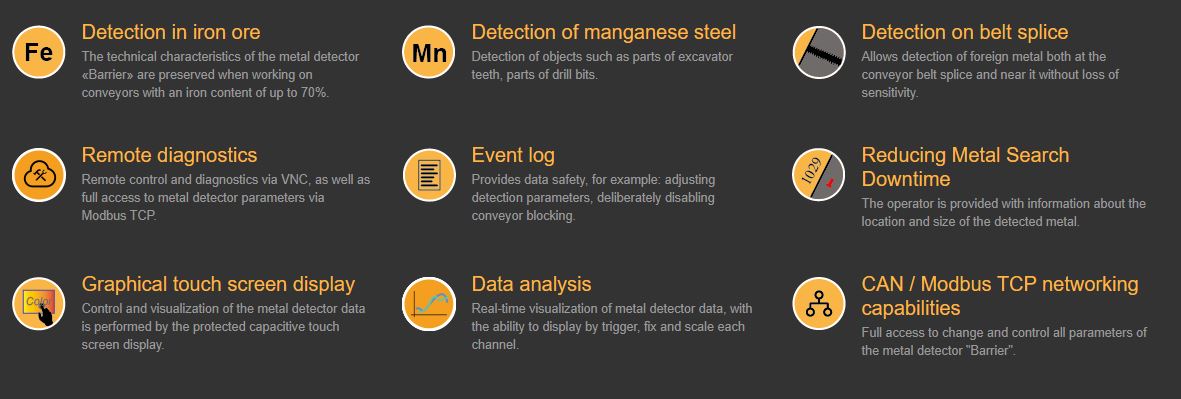

Metal detectors “Barrier” are stationary devices for detection of metal fragments in the flow of moving material with one control zone, automatic control of detection parameters, operating in continuous mode. The metal detector is designed to ensure trouble-free operation of crushing equipment at mining and processing industries by automatic detection of metal fragments from ferrous, non-ferrous metals and their alloys.

The metal detector stops the conveyor for manual extraction (or controls the rectifier station of the electromagnetic separator for automatic removal) when a non-crushable metal fragment is detected, shows the size and length of the detected metal and its position relative to the conveyor sensor on the digital display and graphical display.

Designed to prevent conveyor belt damage due to long rods piercing the belt at transfer points, the Metal Detector «Barrier» in this mode selectively detect only long metal objects of a given length.

The control of the metal detector “Barrier-409” is performed through the graphical interface of the control module 3B409E which is based on a real time system and provides the following additional features:

Auto-change ore profile

Data visualization

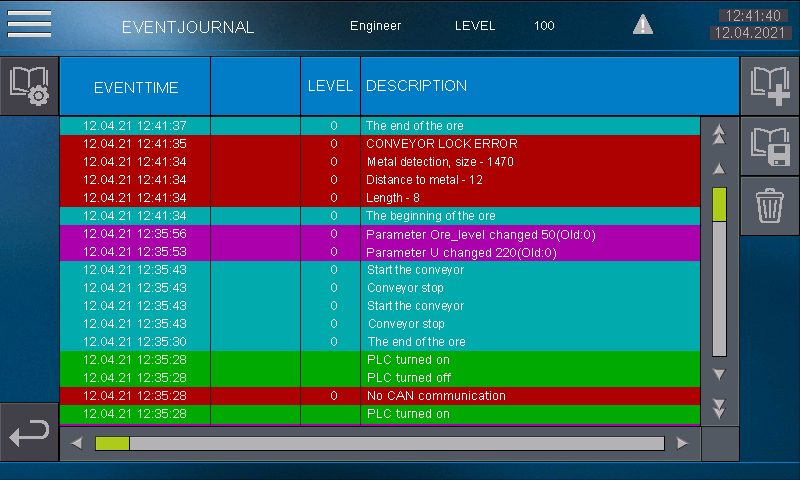

Event log

Ore type profiles

Access control

Remote diagnostics via VNC

Remote software update

Auto-tune in case of the ore change.

In the case of ore changes, auto-tuning is performed by online control of the content of a useful component in iron ore raw materials, comparing the obtained data with the predetermined product profiles and automatic switching of the profiles.

The event log captures all events occurring with metal detectors, sorts and stores them in internal memory with the ability to export to a USB drive:

Conveyor stop lockout error

Сhange settings

Size, length and distance to the detected metal

Ore on the conveyor

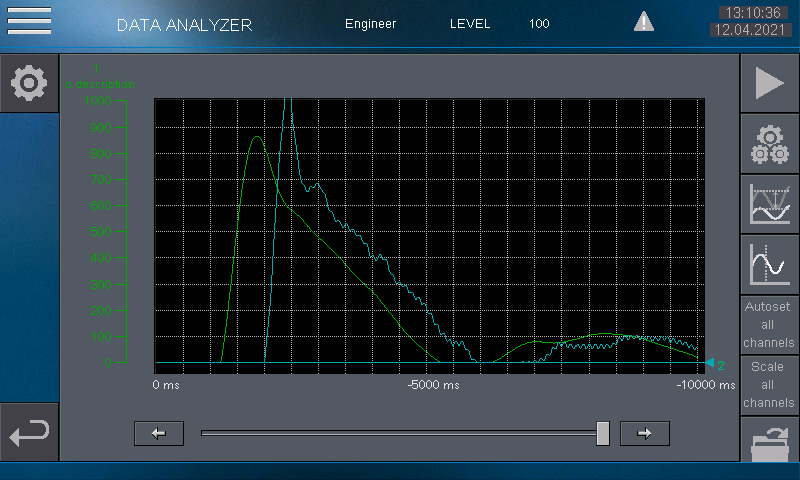

Real-time visualization of metal detector data, with the ability to display by trigger, fix and scale each channel allows the technical specialist of the enterprise or the service of Slavutich Technology LLC to make a fine-tuning or determination:

conveyor state

impact of ore

properties of belt tapes

welding effect

conveyor belt condition

Remote diagnostics

Possibility of remote control via VNC to diagnose and configure the metal detector “Barrier-409”, as well as updating the software.

Features

The difference between models of metal detectors «Barrier»