Our universal WI8101E Integrator

The Dynascales electronics are essential tools for accurately measuring the flow of material on conveyor belts in various industries. However, to ensure that belt scales function properly and provide accurate readings, several accessories are required.

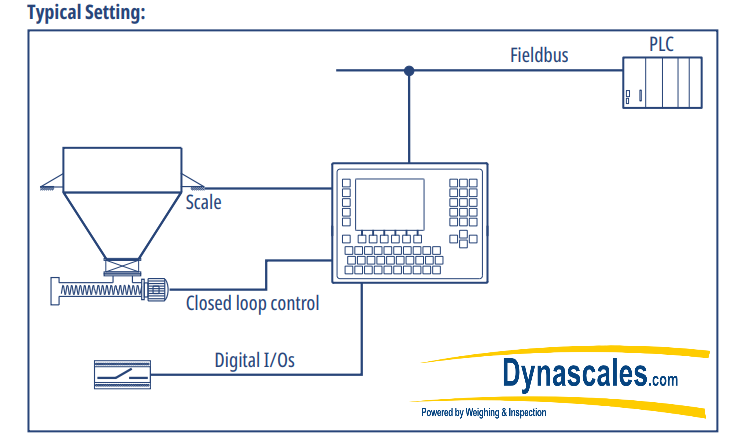

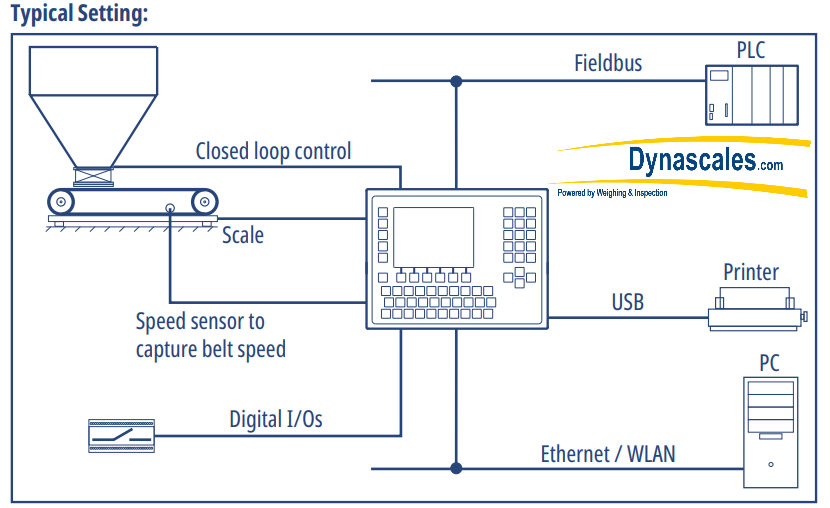

One of the essential accessories for belt scales is an integrator. Integrators process the signal from load cells and calculate the total weight of the material being transported on the conveyor belt. Integrators come in different I/Os and communication protocols, depending on the specific application and the desired level of automation.

WI8101E Integrator

Our universal WI8101E Integrator

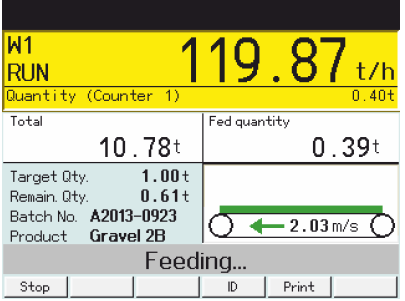

The industrial weighing terminal WI8101e BELT captures continuously the quantity of bulk material conveyed over a belt weigher for both, batching and receiving operations. WI8101e BELT connects to a belt weigher structure with one load receptor with one or several analog loadcells.

The weighing terminal is suitable for harsh environment weighing locations, it is incorporated in a stainless steel desktop / wall-mount or panel-mount housing with high ingress protection.

WI8101e BELT operates as stand alone unit or in combination with a PLC or a SCADA system. It can be configured for the simple capturing of quantities, but also for complex batching applications with preset target and adjustable preact correction.

Powerful PID controller

WI8101e BELT provides a PID controller for feed rate monitoring. The PID controller allows tracking of the actual feed rate with reference to the target by adapting either the material input or the belt speed, through a closed loop control with analog output or connected frequency inverter. The target flow may be adjusted by keyboard, analog input or fieldbus at any time, also during running operation.

Features