Mining

Belt weighers play a crucial role in the mining industry, as they are used to measure the amount of material being transported on a conveyor belt. In the mining industry, conveyor belts are commonly used to transport various types of materials, including coal, iron ore, copper, gold, and other minerals.

Accurate measurement of the amount of material being transported on a conveyor belt is essential for several reasons. First, it helps mining operators to optimize their operations and increase their productivity. By knowing the exact amount of material being transported, operators can adjust the speed of the conveyor belt and other parameters to ensure that the material is being transported efficiently and effectively.

Second, accurate measurement of the material being transported on a conveyor belt is critical for safety reasons. If the material being transported exceeds the capacity of the conveyor belt, it can cause damage to the equipment and even result in accidents or injuries.

Finally, accurate measurement of the material being transported on a conveyor belt is essential for compliance with regulations and standards. Many countries have regulations that require mining companies to accurately measure the amount of material being transported, and failure to comply with these regulations can result in fines or other penalties.

In summary, belt scales are essential tools for the mining industry, as they help mining operators to optimize their operations, ensure safety, and comply with regulations.

Why Dynascales in mining?

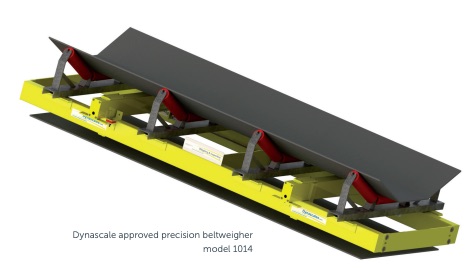

Dynascale 1014 is a belt weigher system designed for the mining industry. Having worked with Thermo Ramsey for years, we use our field experience to create our own product line. It is manufactured in Belgium, Europe and is known for its accuracy and reliability.

The Dynascale belt weigher system DS1014 & DS1020 is designed to measure the amount of material being transported on a conveyor belt. The system consists of load cells, a belt speed sensor, and a microprocessor-based integrator. The load cells measure the weight of the material on the belt, while the belt speed sensor measures the speed of the belt. The integrator calculates the total weight of the material being transported on the belt.

The Dynascale belt weigher system is accurate and reliable because it uses high-quality load cells that are specially designed for the mining industry. We can handle a belt width of more than 3000 mm and a capacity of more than 1000kg/m. The load cells are resistant to harsh environments and can withstand shock and vibration. The system is also easy to install and maintain, which makes it a popular choice among mining operators.

Overall, the Dynascale belt weigher system is a valuable tool for the mining industry, as it allows operators to accurately measure the amount of material being transported on a conveyor belt, which can help them optimize their operations and increase their profitability.