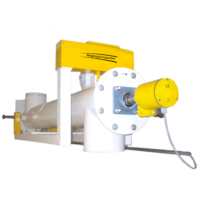

DYNASCREW – screw weighing dosing systems

This reputation is mainly due to the now thousands of dynamic weighing systems that are spread around the world.

However, what many people do not know is that Weighing & Inspection has been applying the knowledge and experience of dynamic weighing for years for weighing chain conveyors and screw conveyors for example.

Basically, the same components are used for a screw weighing system as for a belt weighing system, namely:

- Weighing frame with precision force transducer

- Speed sensor

- Weighing processor

Weighing frame

The weighing frame 10-20SC is derived from the well-known 10-20 belt weighing frame. The weighing frame has already proven reliability and accuracy for more than 45 years.

At the front, the weighframe contains two pivot points between which the feed side of the weighing screw is hung. For proper weighing, it is important that the pivot points continue to function properly. The back of the weighing frame contains a load transducer to which the output side of the weighing screw is hung. The signal from the force transducer is a measure of the product weight in the screw, expressed in kg/m.

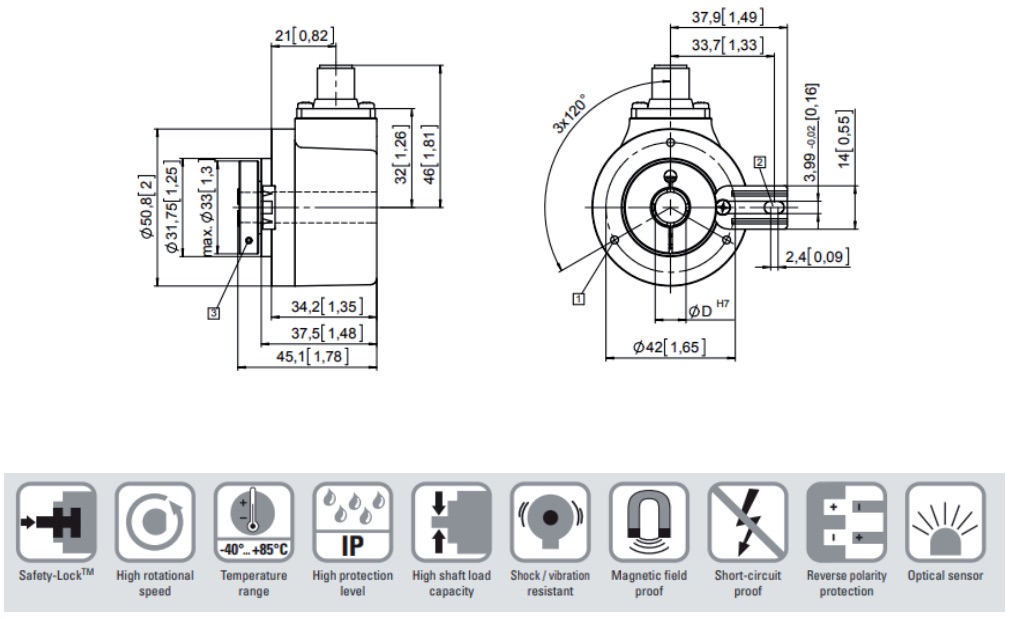

Speed sensor

The digital speed sensor is placed on the axis of the propeller with the help of a linkage. The signal from the speed sensor is a measure of the propeller speed, expressed in m/s.

Dynascrew weigh dosing systems