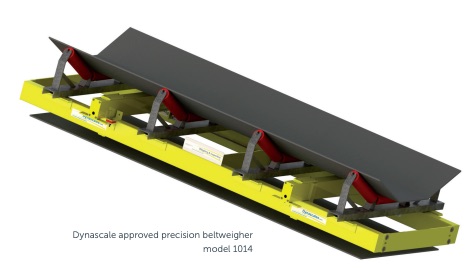

DYNASCALE BELT SCALE MODEL 1014

The Dynascale belt scale model 1014 has an extremely high accuracy that is up to 0.125% and is the most accurate belt scale available on the market. The Dynascale approved belt scale model 1014 allows you to monitor and control your production while providing information on efficient operations. The Dynascale belt scale model 1014 is designed for high accuracies and use in approved applications in the most complex industrial applications. In approved version, you can use the measurement for billing purposes. The belt scale consists of the weighbridge model 1014, with an inner frame suspended on 4 loadcells, the speed sensor WIS526 and the (optionally calibrated) weighing electronics WI301. Both weighing frame, speed sensor and weighing electronics have already proven themselves in practice in approved precision belt weighing systems.

Features and installation

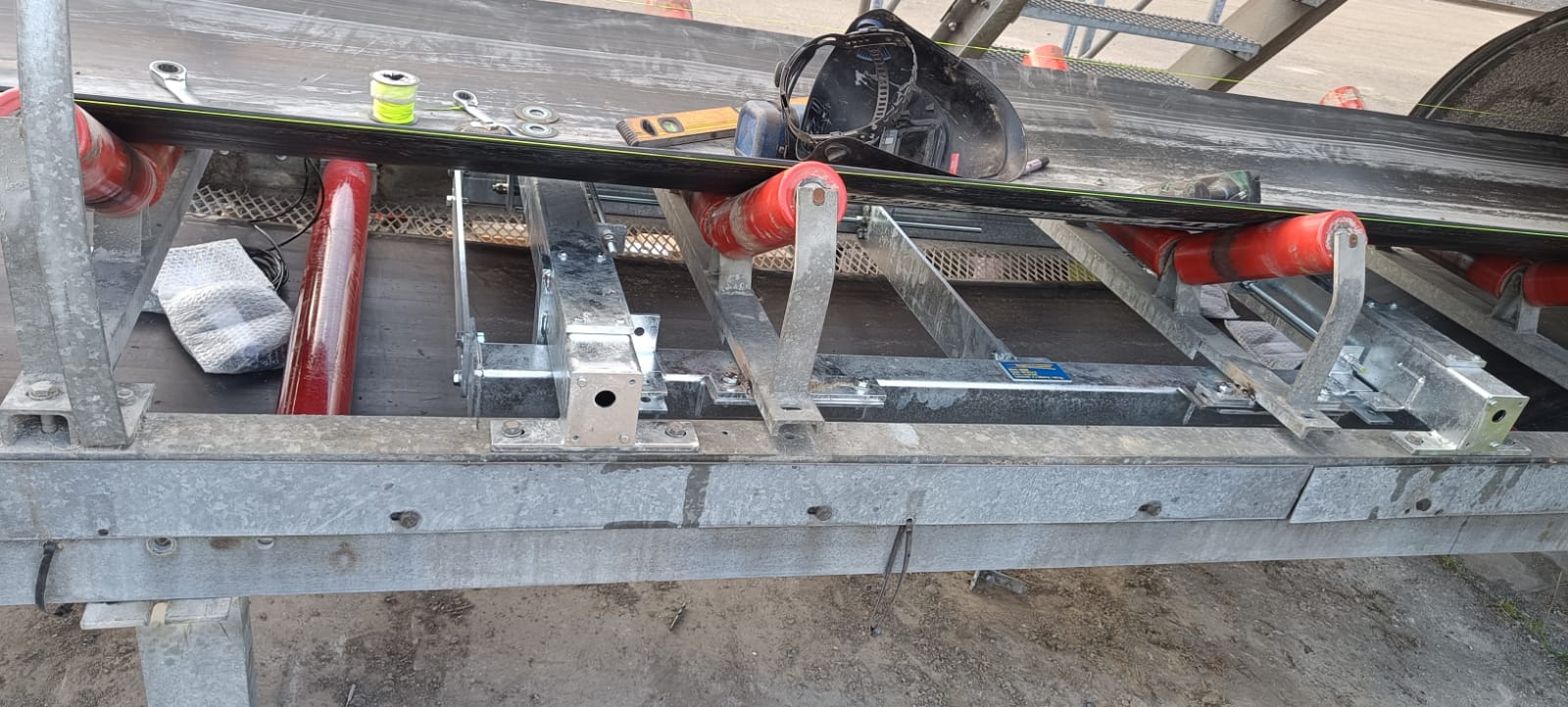

The Dynascale belt scale model 1014 is easy to install, indoors or outdoors, on stationary or mobile belts and is customised to your applications. Its robust construction makes it suitable for the most difficult applications on a wide variety of applications. The Dynascale 1014 belt scale has an OIML certificate according to the EEC directive, class 2, 1 and 0.5.

The weighing frame

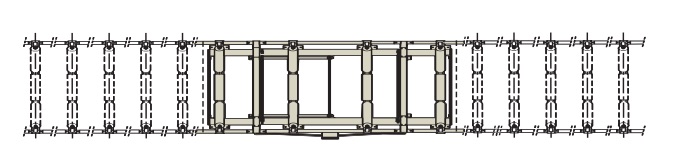

The weighing frame consists of a very rigid inner frame without pivots and moving parts, on which 2, 3 or 4 weighing troughs are placed, depending on the application. The entire weighing frame, including the required tension rods and transport protection, is assembled in our workshop. Only 8 bolts are used to secure the weighing frame in the belt construction. By means of 4 precision load cells, the inner frame is suspended from both load cell beams.

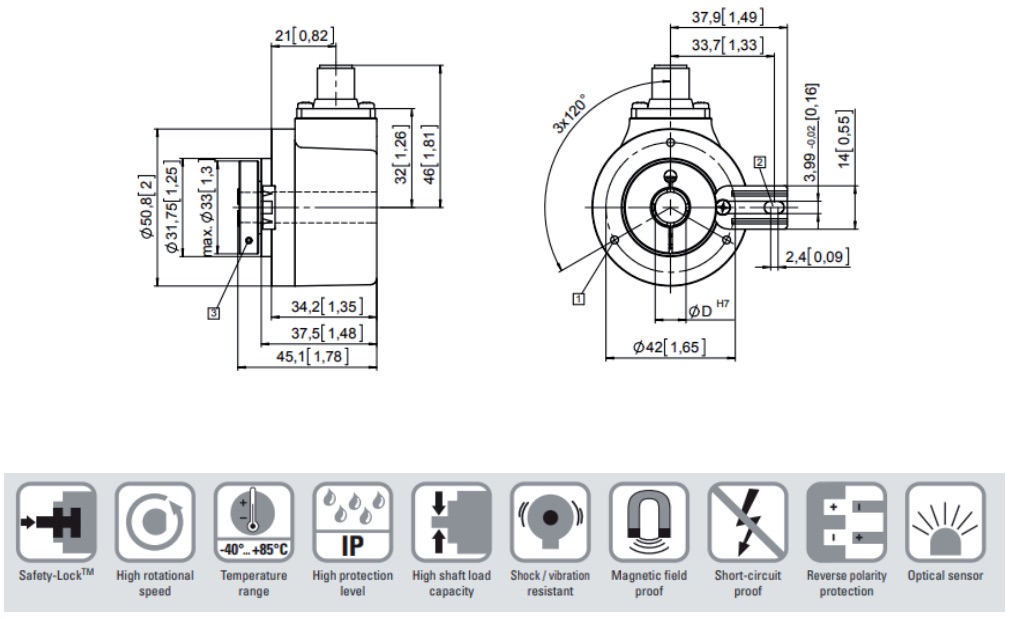

The speed sensor

The digital speed sensor is a highly accurate and reliable speed sensor, ideally suited for use with a belt scale. Its stainless steel construction and IP67 protection degree ensure that it can be used in virtually all conditions, indoors and outdoors, corrosive or not,…

The transducer is mounted on the reversing drum and/or a travel roller on the output shaft, via a rod and a coupling piece to provide a smooth and reliable connection.

The Integrator

The WI301 integrator is a weight integrator for dynamic weighing systems. By integrating the mV signal from the load cells in the weighing frame and the pulse signal from the speed sensor, the WI301 integrator generates a readout for the product flow in e.g. tonnes/hour. It is also possible to read out the belt load (kg/m), belt speed (m/s) and the daily counter or total counter (kg or Ton). The integrator can also be equipped with various optional boards for e.g. communication purposes. The integrator can be used for both approved and non-approved applications.

Accuracy guarantee

On installations approved by us, we guarantee that the Dynascale belt weighing system weighs and counts within a value of +- 0.125 % of the test value, between 20 and 100 % of the maximum capacity, provided it is calibrated with material and the conveyor installation is suitable for it.

Dynascales high precision belt weigher model 1014

Specifications

| Dynascale 1014 weighing frame | |

|---|---|

| Weighing section | 2, 3 or 4 weighing troughs |

| Weighing frame construction | Powder-coated structural steel, optionally galvanised or stainless steel |

| Space requirement | Applicable in any standard conveyor belt |

| Belt widths | 400 to 2000 mm, more on request |

| Mounting | With 8 bolts on the longitudinal beams of the belt structure |

| Loadcell | |

| Number | 4 |

| Type | S-type, IP65 or IP67 |

| Mounting | Loaded under tension |

| Power supply | 10 VDC +-5% |

| Output | 3 mV/V +-0.1% |

| Non-linearity | <0.03 % FS |

| Non-reproducibility | 0.01% FS |

| Operating temperature | -40°C to +80°C |

| Temperature sensitivity Range | 0.0014% FS/°C; Zero 0.0027% FS/”C |

| Overload | Safe to 150% of load cell capacity; Max. to 300% FS; lateral force max. 50% FS |

| Belt speed sensor WIS526 | |

| Type | Digital encoder with hollow shaft |

| Mounting | Directly with a coupling on the output shaft of the reversing drum or a return roller |

| Housing | Stainless steel housing, IP67 |

| Mounting accessories | Shaft with mounting arm |

| Weight | Approx. 500 g |

| Weigh integrator | |

| Type | WI301 |

| Display | Alphanumeric, 5″ colour display |

| Calibration | Zero points, zero point tracking, resistance simulation, weights, calibration chains or product |

| Communication | Protocol of your choice (mA, profinet, profibus, ethernet TCP/IP,…) |

| Power supply | 110 VAC, 240 VAC or 12-30 VDC |

| Digital inputs | Up to 3 |

| Digital outputs | Up to 4 |

| Housing | Field mount IP69K (228 x 214 x 124 mm) or panel mounting, IP69K (241 x 180 x 47 mm) |

| Temperature range | -10°C to +40°C |

| Calibrated version (OIML) | Available, class 2, 1 or 0,5 |