DYNASCALE BELT SCALE MODEL 1030: Advanced belt weighing solution

The Dynascale 1030 belt weighing system accurately measures feed to crushers, mills, sieves, and other processes with exceptional precision, achieving accuracies as low as +- 1-2% even in the most challenging conditions.

Efficient monitoring and control

Our process belt scale model 1030 enables you to effectively monitor and control your production processes, providing valuable insights for optimizing efficiency and operations.

Designed for process belt weighing in complex industrial environments, the Dynascale 1030 belt weigher offers precise control over material supply, enhancing overall operational efficiency.

Backed by the proven reliability of the 1030 weighing frame, featuring the 526 speed sensor and the advanced WI301 weighing electronics, our Dynascale 1030 belt weigher delivers unparalleled performance and versatility.

Easy installation

The Dynascale belt scale model 1030 is easy to handle and install by simply 4 bolts, indoors or outdoors, on stationary or mobile belts. Its robust construction makes it suitable for the most difficult applications on a wide variety of applications.

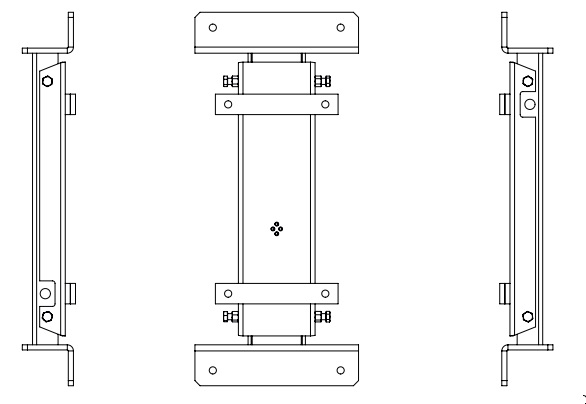

The weighing frame

Its sleek and robust construction keeps the 1030 weighing frame fully in line with the conveyor frame. This one-piece weighing frame is fully assembled at the factory and is quick and easy to install and integrate into the conveyor belt. The weighing frame is designed to provide additional support and reinforcement to the belt structure, thus minimising deviations. The weigh frame 1030 offers is using 1 or 2 loadcells, depending on the application and belt width and insensitive to vibration, moisture and product accumulation, unlike many other systems.

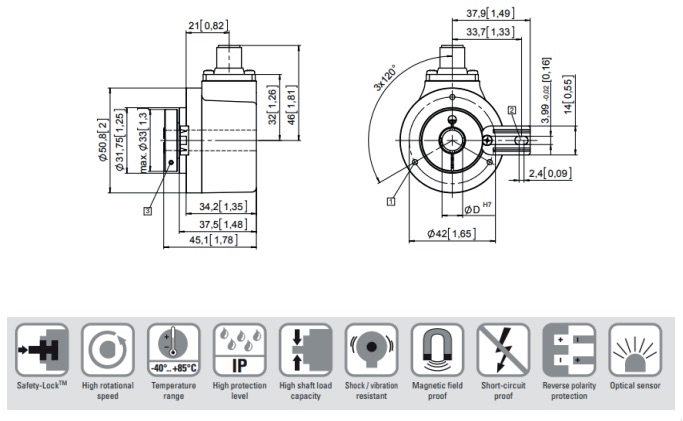

The belt speed sensor

The WIS526 digital speed transducer is the most reliable and accurate speed transducer ever developed for use with belt weighers. By directly connecting the transducer to the belt reversing roller or a return roller, you are guaranteed an accurate belt run reading. No wheels running over the belt, preventing problems caused by product accumulation or belt slip.

Dynascales precision belt weigher model 1030

Specifications

| Dynascale 1030 weighing frame | |

|---|---|

| Weighing section | Single trough frame weighing frame |

| Weighframe design | Composed of a weighing platform suspended in pivots and a support beam placed transversely over the conveyor frame. The rigid construction thus reinforces the weighing section of the conveyor. |

| Weighing frame construction | Powder-coated structural steel, optionally galvanised or stainless steel |

| Space requirement | Applicable in any standard conveyor belt |

| Loadcell | |

| Number | 1 or 2 |

| Type | Single point, stainless steel, IP68, ATEX optional |

| Mounting | Load on traction |

| Power supply | 10 VDC +-5% |

| Output | 2 mV/V +- 0.1% |

| Combined error | <0.0175 % FS |

| Non-reproducibility | 0.01% FS |

| Operating temperature | -10°C to +40°C |

| Temperature sensitivity Range | 0.00093% FS/°C; Zero 0.00088% FS/°C |

| Overload Safe | To 150% of load cell capacity; Max. to 300% FS |

| Belt speed sensor WIS526 | |

| Type | Digital encoder with hollow shaft |

| Mounting | Directly with a coupling on the output shaft of the reversing drum or a return roller |

| Housing | Stainless steel housing, IP67 |

| Mounting accessories | Shaft with mounting arm |

| Weight | Approx. 500 g |

| Weigh integrator | |

| Type | WI301 |

| Display | Alphanumeric, 5″ colour display |

| Calibration | Zero points, zero point tracking, resistance simulation, weights, calibration chains or product |

| Communication | Protocol of your choice (mA, profinet, profibus, ethernet TCP/IP,…) |

| Power supply | 110 VAC, 240 VAC or 12-30 VDC |

| Digital inputs | Up to 3 |

| Digital outputs | Up to 4 |

| Housing | Field mount IP69K (228 x 214 x 124 mm) or panel mounting, IP69K (241 x 180 x 47 mm) |

| Temperature range | -10°C to +40°C |

| Calibrated version (OIML) | Available, class 2, 1 |